89 A/3, Roshan Garden New Delhi-110043

Call Us Today:

9873028756

Quality Management System

the organization that impacts its qms

determined and considering life cycle perspective.

thinking and improvement

EHS & Energy Management System: 14001, OHSAS 18001 & ISO 50001

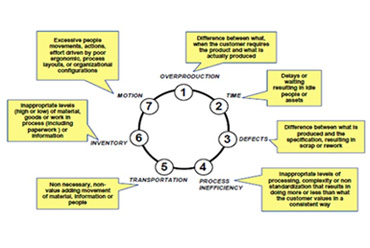

Lean Manufacturing

Diagnostic study and gap presentation

Purpose

Deliverables

Ceo congress

Purpose

Deliverables

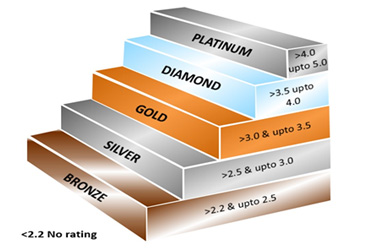

Zero Defect and Zero Effect

Awareness

Purpose

Deliverables

Gap analysis

Purpose

Deliverables

Hand holding & consulting

Purpose

Deliverables